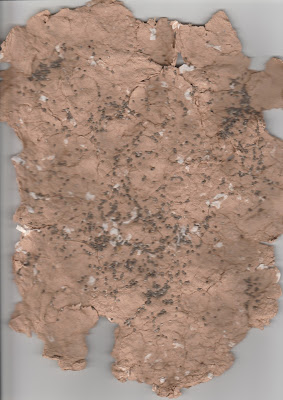

Overall, within this COP3 Module I believe I have done a reasonable amount of work within both my essay/dissertation and practical . However, I believe I could of done a lot more specifically in my practical work. For example, I was not able to do everything I wanted on time due to lots of trial and errors of making recyclable paper slowed my process down a lot and it was important to get the paper especially accurate as it is the main purpose of my practical work. Next were digital work such as mock-ups, I was unable to complete everything due to timing reasons. In the practical work, instead of the packaging having a label of what ingredients are in the sandwiches, allergies, fat, calories and so on. Were supposed to be on the supermarket shelf labels instead, unfortunately I had no time to do this. In addition, editing photos for my final design and GIF, short animation also slowed me down due to the technical problems of making the animation work and the time lapse of the packaging transforming into a plant look professional. For example, having subtitles explaining the process or ever a narration and background music for the short advert. If I had more time or if I was more conscious of my time I would refine these to make the practical work of the sustainable sandwich packaging more sleek.

Whereas, my essay/dissertation was a lot better than I expected. Even though, the question that I originally had was quite broad the one I narrowed down called 'Is Sustainability in food packaging actually sustainable' had a lot of information and research to look into. I was able to do a triangular with the theorist and authors who had similar yet different approaches to sustainability. But through their philosophies that I researched I was able to come up with a new cycle of reverse engineering a packaging product. This is thinking about more the death of the product and what it will become. Then it becomes the birth of the actual products function and then comes to life. The cycle repeats itself so there will not be any wasted unnecessary material nor food waste in the process.

To recap, I am happy with the amount of work that I produced in this module. I still believe I could make the practical more refined, sleek and more professional looking if I organised myself efficiently. Nevertheless, I believe my essay/dissertation was written out well with the information I collected and finding a new strategy of producing sustainable food packaging that consist of 'Waste equals food' concept.